- In addition to the tools offered in the Moldplus Standard product, the following tools are available:

Electrode Maker

- Improved interface to select geometry and create electrodes

- Preview selected stock before inserting electrode

- Create chamfers on stock at any desired corner

- Multi-step electrode extensions in 1 click (tangential, draft, junction plane and angle and fillet) to build strong machine-able electrodes for single or multiple geometry selections

- Copy and XForm created electrodes to new locations to optimize electrode creation

- Create output file with machining data for electrode machine

|

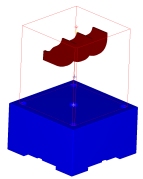

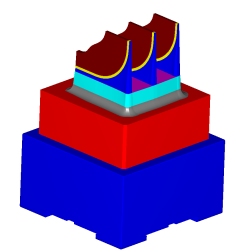

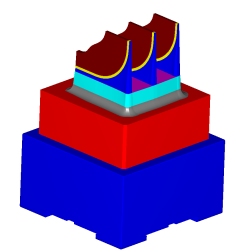

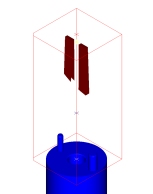

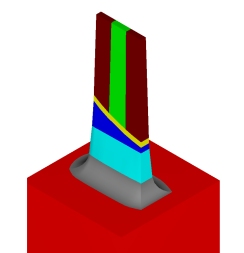

With 1 click, create electrodes with multiple extensions! |

|

|

|

|

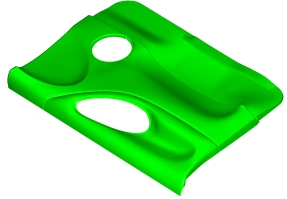

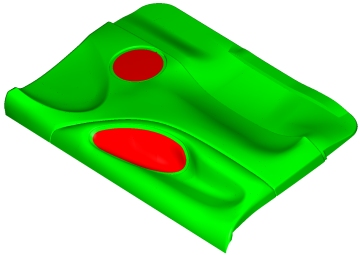

Electrode geometry prior to creating extensions. |

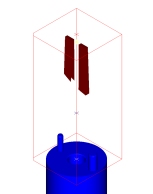

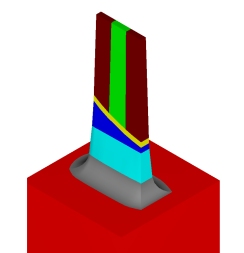

Create tangential or ruled junction surfaces by clicking on surface edges to connect them!

|

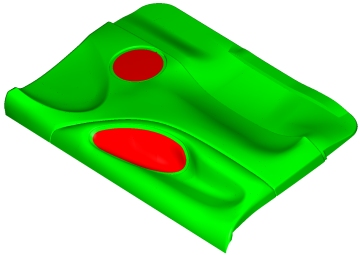

With an additional click, create all the surface extentions for the electrode geometry. |

- Wizard interface and detailed Electrode Job Setup parameters

- Automatic creation of standard electrode forms (flat, round, square), including the type of material (copper or graphite) and holder (3R or EROWA standards)

- One click selection of depressions or bosses which typically define an electrode

- Automatic selection of the standard electrodes relative to the selected geometry in order of minimal stock needed

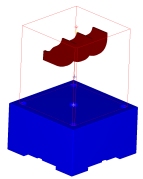

- Automatic placement in absolute coordinates of the standard electrode with a preview of the electrode insertion

- Angular insertion of electrodes to minimize rough stock use

- Automatic collision detection between the electrode holder and the part

- Automatic electrode surface extensions (tangential, draft, etc) to build strong electrodes for machining and burning

- Copy and transform created electrodes to new locations to burn identical electrodes

- Save the standard electrode with geometry to be machined to a level in the file and/or a separate file for easy management.

- Easy preparation of electrodes (properly orienting the electrode by rotation\transformation, etc) for machining.

- Generate HTML Shop Floor documentation reports on all electrodes created with images and information relevant to burn location, electrode dimensions / etc.

|

Modify Surface Trims

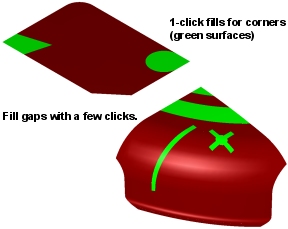

- Superior surface un-trimming tools to split or fillcomplex cuts with1 click!

- Create junction surfaces as tangential or ruled surfaces between surfaces that do not share a common base surface with 2 clicks!

- New Surface Trim Editor that allows you to manipulate the boundaries of trim surfaces! Easily extend, shorten or insert cuts within trimmed surfaces!

|

|

|

| Select Surface to edit node points of trim. |

Dynamically drag the surface trim node point. |

Modified trim boundary of trimmed surface. |

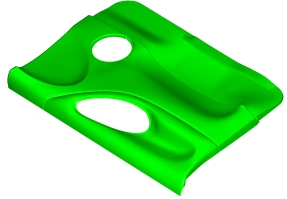

Using the Junction surface tool, fill complex holes with tangential or ruled surfaces between independent surfaces with a few cliks!

|

|

|

| |

Fill holes on the door with a few clicks. (Red Surfaces) |

|

|